In modern manure treatment, every pig farm, biogas plant, and organic fertilizer production line faces the same challenge: pig manure usually contains 80–90% water. High-moisture pig feces cause storage problems, odor issues, and low efficiency in fertilizer production. Therefore, every producer needs a stable dehydration and drying process, not only for agricultural use, but also for industrial-scale organic fertilizer manufacturing. Among various solutions, rotary drum dryer systems often give the most efficient water reduction results for pig dung processing.

What types of high-moisture raw materials need efficient dehydration in pig manure processing?

Many industries handle high-moisture organic waste, and pig feces belong to the most typical category. Pig manure sludge from pig farms usually shows moisture content around 85%. Biogas residue from anaerobic digestion, pig dung mixed with bedding materials, and pig manure mixed with food waste or crop straw also present similar characteristics. Each type of pig feces material requires different dehydration and drying levels before further processing.

For example, organic fertilizer production plants often use pig manure mixed with chicken manure or cow dung as raw material. These producers need a reliable pig manure dewatering process to reduce moisture from about 85% to around 60% in the first stage by a manure dewatering machine or screw press separator. This initial dewatering equipment improves handling, reduces volume, and prepares pig feces for composting.

Biogas projects also treat high-moisture pig dung residue. The operators usually transfer the digestate to a solid–liquid separation machine, then send the separated pig manure solids to the composting system. After fermentation and compost turning, the material moisture drops further, which supports the next stage of pig manure fertilizer granulation. Each sector—pig farms, biogas plants, and organic fertilizer manufacturers—requires stable moisture reduction, efficient pig feces processing, and consistent pig manure fertilizer quality.

How does a complete pig manure fertilizer production process manage staged water reduction?

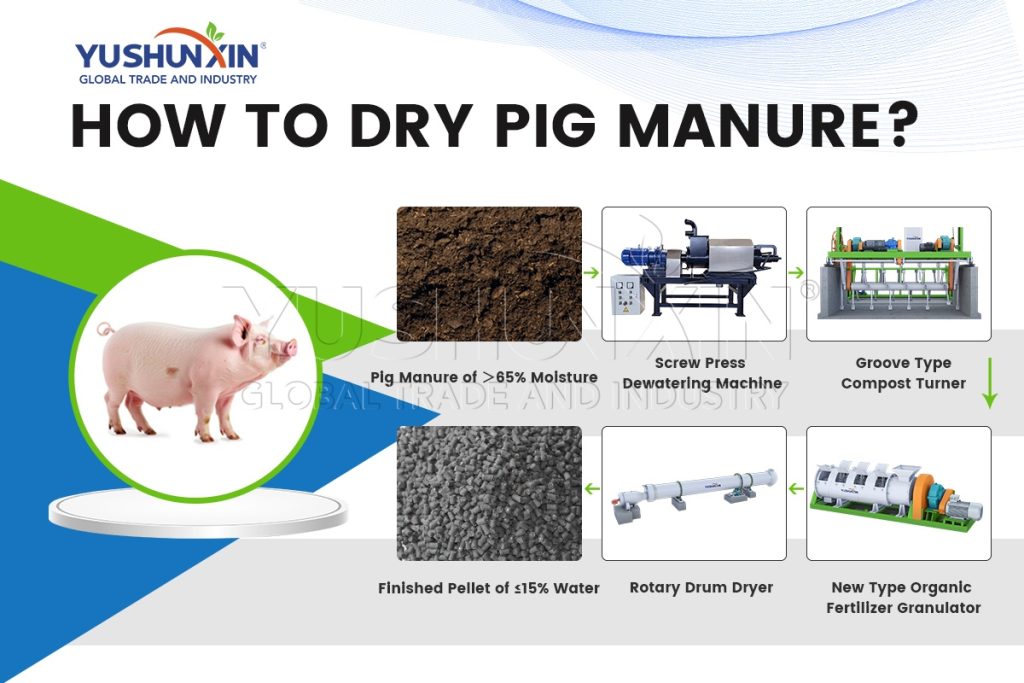

A typical pig manure fertilizer production line does not complete dehydration in one step. It usually follows a four-stage moisture reduction procedure, and every stage uses specific equipment. This sequence influences the final pig dung fertilizer quality and the performance of granulation and drying machinery.

In the first stage, a manure dewatering machine or solid–liquid separator reduces pig feces moisture from about 85% to around 60%. This mechanical dewatering step lowers transport costs and prepares the material for biochemical treatment. In the second stage, a composting machine, compost turner, or fermentation system handles pig manure composting. Continuous aeration and turning gradually reduce water content to roughly 50% and stabilize organic matter.

The third stage usually includes a wet granulator, such as a disc granulator, drum granulator, or specialized pig manure pelletizer. During granulation, the pig manure compost becomes granules or pellets with moisture of about 30–40%. This pig manure granulation process creates uniform particles for fertilizer production, but it also introduces additional water due to binding and shaping. Therefore, the fourth stage always requires a reliable drying system. At this point, a rotary drum dryer reduces granule moisture down to below 10%. This final moisture reduction step ensures pig manure fertilizer storage stability, improves pellet hardness, and reduces caking in bags or bulk storage.

Why do pig manure fertilizer producers prefer rotary drum dryers for final dehydration?

In many pig manure fertilizer plants, rotary drum dryers become the core dehydration equipment in the last stage of water reduction. This drum-type dryer handles granules, pellets, or fine particles after composting and granulating. The design matches the characteristics of pig dung granules, which often show sticky surfaces and variable size. A rotary drum dryer gives continuous tumbling and cascading of the material, so every pig manure particle contacts hot air repeatedly and achieves uniform drying.

Producers value rotary drum dryer systems because these machines support large processing capacity, stable moisture control, and efficient energy utilization. The internal lifting plates and drum design control material residence time and promote thorough moisture reduction. The system usually connects with a hot air furnace, induced draft fan, and dust collection unit, which forms an integrated pig manure drying line. This complete drying equipment helps pig manure fertilizer plants keep granule moisture under 10%, which suits long-distance transport and long-term storage.

Furthermore, a rotary drum dryer easily combines with a pig manure granulator or pelletizer at the upstream and a cooling machine and screening machine at the downstream. This integration supports continuous pig manure fertilizer manufacturing and reduces labor intensity. Producers who operate large pig dung pellet making lines often choose rotary drum dryers because these drying machines match high throughput, stable quality control, and long service life requirements in industrial organic fertilizer production.

How does rotary drum dryer performance compare with other pig manure dehydration equipment?

Each stage of pig manure processing uses different technologies, and every machine serves a specific function. A dewatering machine handles initial pig feces moisture reduction, but this equipment only reduces water to about 60% and cannot replace high-temperature drying systems. A composting machine promotes fermentation and partial natural drying, but it still leaves 40–50% moisture, which does not satisfy pig manure fertilizer storage standards. A wet granulator, such as a pig dung ball making pelletizer, shapes fertilizer granules, yet it often increases surface moisture and makes additional drying necessary.

In contrast, a rotary drum dryer targets the final critical dehydration stage for pig manure fertilizer granules. This drying machinery reduces moisture from 30–40% down to less than 10%, and it does so in a controlled and continuous process. The drum-type design tolerates variations in pig feces composition, granule size, and feeding rate. At the same time, the system allows operators to adjust inlet air temperature, drum speed, and residence time according to different pig manure fertilizer recipes and production capacity.

Consequently, pig manure fertilizer producers usually combine different types of equipment into one process line: dewatering machine for initial water removal, composting equipment for fermentation and partial drying, wet pig manure granulator for particle formation, and rotary drum dryer for final water reduction. This integrated design ensures stable pig dung fertilizer quality, high output, and consistent granule or pellet performance in the market.

How should pig manure processing plants choose a suitable rotary drum dryer system?

Every pig manure fertilizer factory needs to evaluate several aspects before selecting a rotary drum dryer. The design should match daily processing capacity, inlet moisture content, and target moisture for pig manure granules or pellets. The producer also needs to consider fuel type, such as coal, natural gas, biomass, or biogas from pig manure digestion. The drying system layout, including heat source, air flow design, and dust control equipment, should comply with local environmental requirements.

A well-designed rotary drum dryer system optimizes heat transfer and material movement, so pig feces granules dry evenly and maintain strength during handling. At the same time, the system should work smoothly with upstream pig manure composting and granulation equipment as well as downstream cooling and screening machinery. Proper matching between rotary drum dryer capacity and pig manure pelletizer output prevents bottlenecks and guarantees continuous fertilizer production.

Producers who need a specialized solution for pig manure fertilizer dehydration can cooperate with an experienced drying equipment manufacturer. A professional drying equipment manufacturer—Yushunxin—offers rotary drum dryer systems, manure dewatering machines, composting equipment, and wet granulators, and therefore supports complete pig dung fertilizer production lines from initial dewatering to final drying and packaging. You can visit: https://www.fertilizerdryer.com/how-to-dry-pig-manure/